Introduction

Due to popular demand, we have compiled a book detailing the concept, history, methods, and applications, that we will publish periodically!

C-Cell measures a wide range of slice size and shape properties and internal crumb cell structure characteristics. The objective data produced by C-Cell is used by all involved within the baking industry, from flour millers and ingredient producers to bakery equipment manufacturers, plant breeders and researchers providing a comprehensive interpretation of product properties.

Not all of the individual C-Cell measurements are likely to be used in every study. Deciding on which properties to use in a particular evaluation comes with experience. We recommend that you carry out some preliminary studies with a range of product structures with a view to gaining experience as to which particular measurements reflect observable and useful differences in the test samples.

We also recommend that you measure more than one slice for each product being evaluated. The properties of individual slices will vary along the product length and the degree of this variation should be assessed so that a standardised sampling pattern can be established for particular groups of products. For example, large variations in cell elongation and average cell diameter are commonly seen with four-piece moulded bread depending on where the slice has been taken from the loaf.

Instrument concept, History & Evolution

Instrument concept

In early 2000 a major global plant bakery in the UK funded a private members project with Campden BRI to look at utilising Image analysis to quantify the internal structure of bread. The aim of the project was to move away from subjective sensory panel assessment to a more objective method of assessment.

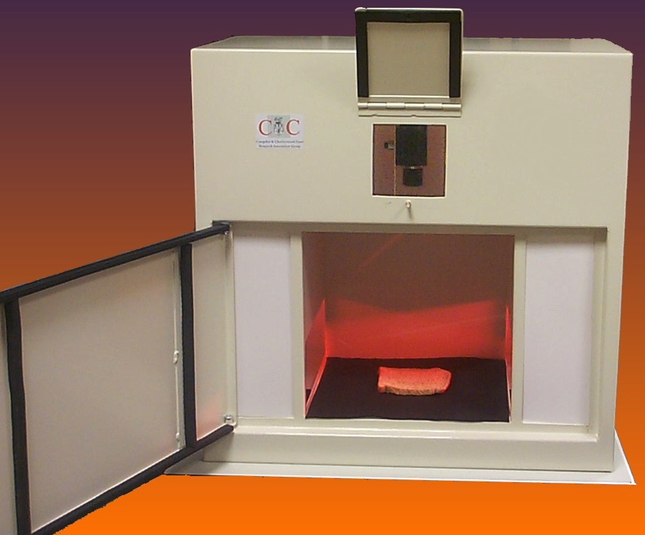

The illumination is specially designed to provide detailed and consistent analysis and emphasises surface textural differences

History

A major global plant bakery in the United Kingdom funded a private project with Campden BRI to look at the possibilities of using Image analysis and bespoke software to analyse the internal structure of bread samples.

In December 2001 they delivered the prototype to the plant bakery as proof of concept. An Image was taken using shallow angle illumination and processed in a bespoke computer programme written by Campden.

Towards the end of 2001 the two companies opened discussions with Calibre Control International Ltd about commercialising the system.

In November 2002 C-Cell was launched by Calibre and Campden BRI. Calibre being responsible for manufacturing and global marketing and Campden produced the software.

Instrument configuration at launch in 2002

Monochrome configuration

In 2004 Version 2 software was launched, running on Windows XP

In 2010 Calibre acquired total control of C-Cell.

System Evolution

2002 – C-Cell Monochrome launched with Version 1 software

2004 – C-Cell Monochrome Version 2 software available

2010 C-Cell Monochrome supplied with Version 2.5 software running on Windows 7

In 2012 LED lighting replaced the Halogen bulbs

In 2013 C-Cell colour was launched with Version 2.5 software running on Windows 7

In 2016 Version 3 software, including “Developer programme” launched on Windows 7

In 2017 Version 3 software running on Windows 10

Colour configuration:

Current models and versions

C-Cell monochrome

CC.302 C-CELL Bread Imaging System – Version 2

Imaging System– Cabinet with optics, lighting and sample presentation system.

Analysis Software– Dedicated image analysis software to measure characteristics of product surfaces. The software measures many aspects of the size and shape of the sample, its cell structure and features. A selection of images is available to aid visualisation of the particular aspects of the sample.

Computer – Computer suitable for C-Cell with preloaded software and camera driver board.

The system is suitable for a number of Product Types and provides Crumb Cell measurements and images.

Data Management is provided by an integral database or exported in common file formats for further analysis. A printable report output is also provided.

CC.303 C-CELL Bread Imaging System – Version 2 Advanced

Imaging System– Cabinet with optics, lighting and sample presentation system.

Analysis Software– Dedicated image analysis software to measure characteristics of product surfaces. The software measures many aspects of the size and shape of the sample, its cell structure and features. A selection of images is available to aid visualisation of the particular aspects of the sample.

Computer – Computer suitable for C-Cell with preloaded software and camera driver board.

Advanced data output of 5 parameters for each cell identified:

Area

X position

Y position

Elongation

Volume

The system is suitable for a number of Product Types and provides Crumb Cell measurements and images.

Data Management is provided by an integral database or exported in common file formats for further analysis. A printable report output is also provided.

C-Cell Colour

CC.400 C-CELL Food Structure Imaging System – Version 3

Colour Imaging System– Cabinet with 3 chip colour camera, dual lighting and sample presentation system.

Analysis Software– Dedicated image analysis software to measure characteristics of product surfaces. The software measures many aspects of the size and shape of the sample, its cell structure and features. A selection of images is available to aid visualisation of the particular aspects of the sample.

Crust Profiling

Crust Thickness

Crust Colour

Crumb Colour

Inclusion Analysis

Computer – Computer preloaded with software.

The system is suitable for a number of Product Types and provides Crumb Cell measurements and colour analysis.

Data Management is provided by an integral database or exported in common file formats for further analysis. A printable report output is also provided.

CC.410 C-CELL Food Structure Imaging System – Version 3 Advanced

Colour Imaging System– Cabinet with 3 chip colour camera, dual lighting and sample presentation system.

Analysis Software– Dedicated image analysis software to measure characteristics of product surfaces. The software measures many aspects of the size and shape of the sample, its cell structure and features. A selection of images is available to aid visualisation of the particular aspects of the sample.

Crust Profiling

Crust Thickness

Crust Colour

Crumb Colour

Inclusion Analysis

Computer – Computer preloaded with software.

The system is suitable for a number of Product Types and provides Crumb Cell measurements and colour analysis.

Advanced data output of 5 parameters for each cell identified:

Area

X position

Y position

Elongation

Volume

Advanced Developer Software Module

Software for inclusion/external feature analysis

Data Management is provided by an integral database or exported in common file formats for further analysis. A printable report output is also provided.